Idler Wheel rebuilding is now available! Mail in your old idler wheel for service. New rubber is bonded to the existing wheel and then cut to correct size and shape. Single disk idlers cost $40.00 to rebuild. Double-disk idler wheels cost $55 to rebuild. The center hole can also be re-machined in brass or nylon, if necessary, for $15 extra. If you want the hub re-machined, then you will need to measure the diameter of the hub spindle to an accuracy of .001 inches (or .01 mm) with a dial caliper or micrometer and get that measurement to us with the old wheel. If your idler wheel is missing, we can also fabricate a new one for you - but we will need accurate measurements of the hub spindle, wheel thickness and outer diameter. Turnaround time is four weeks. Send your old idler wheel with payment to: Turntable Basics, 550 N Lexington Pkwy, St Paul, MN, 55104, USA.

Single Disk / Single Radius Idler Wheel Rebuild $40.00Shopping Cart Supports Paypal, Visa, MasterCard, and American Express |

Double Disk / Double Radius Idler Wheel Rebuild $55.00Shopping Cart Supports Paypal, Visa, MasterCard, and American Express |

Pinch Roller Rebuilding for Tape Recorder Transports $55.00Shopping Cart Supports Paypal, Visa, MasterCard, and American Express |

Yes, this wheel can be rebuilt. Wheels which lose friction tend to slip. This creates heat. |

Single Disk Idler Wheel |

Single Disk Idler Wheel |

Single Disk Idler Wheel |

Single Disk Idler Wheel |

Single Disk Idler Wheel |

Single Disk Idler Wheel |

Single Disk Idler Wheel |

Single Disk Idler Wheel |

Double Disk Idler Wheel |

Double Disk Idler Wheel |

This large wheel (more than 3 inches in diameter) is from a Gates Broadcast Table. It is billed as a double disk idler because of its two-step outer rim. |

This wheel is held in place by an E-Clip. It is easily removed by sliding it to the left with a slotted screwdriver. |

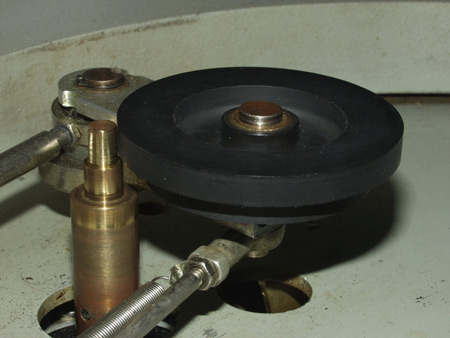

This is a common double disk idler wheel setup. The wheel is mounted on an arm which pivots and forces the wheel against the platter. A belt connects drives the belt off of the motor spindle (right). Speed is selected by raising the pivoting arm up and down. This wheel has flat spots from storage and is cracked. |

A similar double disk idler drive setup, from the Gates table. |